|

| The Number 19 at Orford Junction. |

Like everyone, I work on a project for a while, get tired of it, quit, and, hopefully, get back to it some time later. A couple of years ago, I refitted almost all of my locomotives with Tsunami sound decoders. By the time I had finished most of them, I got tired of the project and left two locos silent and running with only non-sound decoders. Over the last couple of days, I finally decided to remedy that situation and install the sound decoders.

|

The speaker can barely be seen at the left rear corner of the tender. A Sagami 16x30 motor was used.

|

|

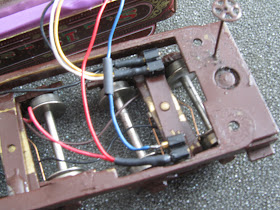

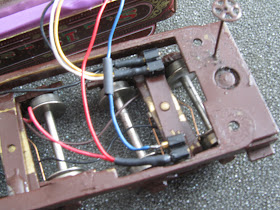

| Some of the tender frame had to be removed to allow the decoder to fit. |

The two engines in need were No. 19, a Pacific Fast Mail import of the V&T

Reno. This engine is a 4-4-0 with the motor, decoder and speaker in the tender. There is precious little room for all these things, so little in fact, that I had to skew the motor slightly to allow the Tsunami to fit. Many people think that a motor in the tender will result in "tender wobble" as the loco runs. This is not the case. If a rubber tube coupling is used between the engine and motor, you can expect the wobble but not if Northwest Short Line U-joints are used. The drive shaft between the engine and tender is not real noticeable and there is more room in the engine for weight which means long trains. My 4-4-0s pull 10-12 normal-sized cars without a problem.

The speaker I used was a Soundtraxx 3/8" speaker. It's not real big but it does put out the necessary sound and it's the only one that I can get to fit. It's located at the extreme rear of the tender behind the flywheel.

|

The motor is attached to the tender shell. Screws are covered by the wood load.

|

|

The Number 16 at Stockton. It is still lettered for the MSN but the tender will be repainted and relettered for the Stockton & Copperopolis.

|

The other engine was No. 16, the Stockton switcher. It had a small Lenz decoder in it which gave good results but no sound. Another Tsunami went in here. There was enough room to add a big larger rectangular speaker I had. Everything was a tight fit due to the slope of the tender deck but it now works well and will please the Stockton yardmaster who was complaining about having an engine without sound.